CORNICE INSTALLATION GUIDE

Discover the secrets to effortlessly achieving a flawless and polished look with our user-friendly DIY cornice installation guide!

Effortless Installation for Stunning Results!

SHADOWLIGHT CORNICE INSTALLATION

Transforming your space has never been easier with our range of high-quality cornices. Designed with simplicity in mind, our cornices allow you to achieve professional-looking results in no time!

Whether you're a seasoned DIY enthusiast or a novice looking to embark on your first home improvement project, our user-friendly installation guide is here to support you every step of the way.

Ready to transform your space? Watch our easy installation video to help you get started!

Our range of cornices are the perfect decorative element that can transform any room with minimal effort. The best part? Installing cornice decorations are a breeze! Here's a step-by-step guide to help you achieve stunning results in no time:

Step-by-Step Guide

CORNICE INSTALLATION MADE EASY

-

For your cornice installation you will need:

Your chosen ShadowLight polystyrene cornice lengths

A measuring tape, a pencil

A chalk line

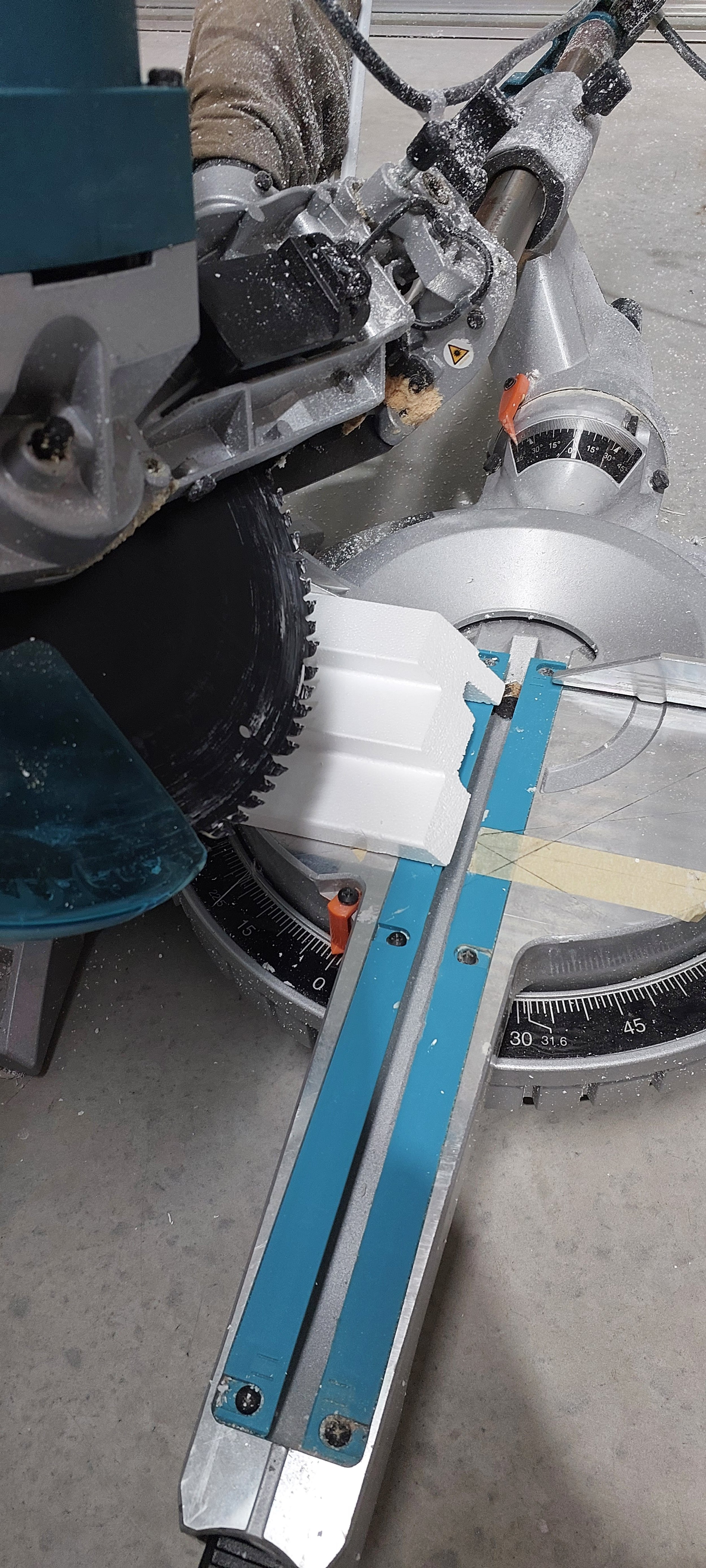

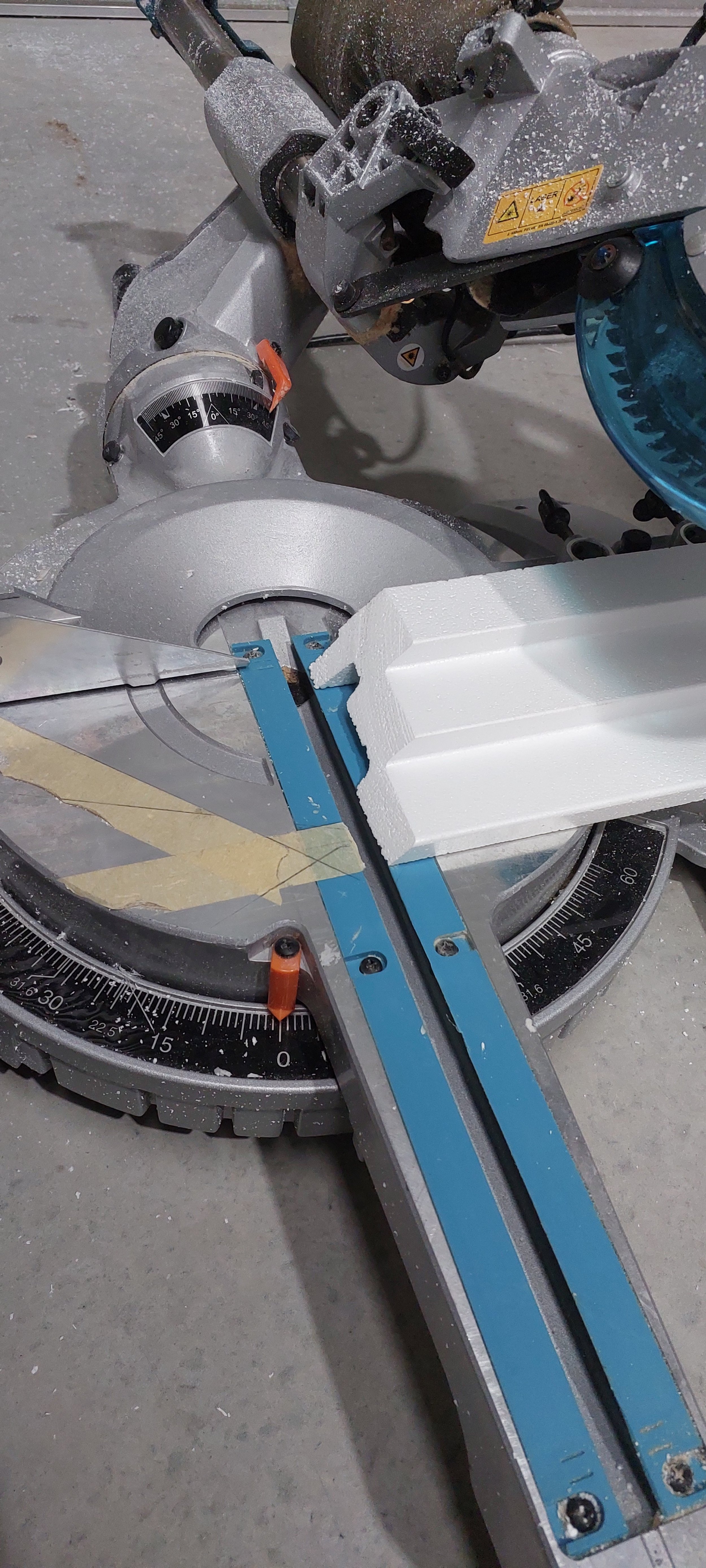

A mitre box or power mitre saw

A ladder

A scraper

Water

Paintbrush.

-

Carefully mark the desired positions for the cornice along the first wall of your room with a light pencil line.

Measure from the ceiling straight down, considering the width of your chosen design, and connect the marked points with a chalk line.

If you're installing LED lighting with your ShadowLight Cornice, allow an additional 2 to 2.5cm for the required gap.

Repeat this process for all the walls of the room.

Now, measure the length of the first wall where you plan to install the cornice.

-

Cut the angles for the first corner.

Most corners are 90 degrees (right angle) so they will require a 45-degree cut.

If a corner is not 90 degrees, use a protractor to determine the necessary cutting degrees and adjust your cutting angle accordingly.

Cut the cornice with your mitre saw or mitre box.

Fit the cut cornice pieces together to ensure the edges are a perfect fit before proceeding to the next step.

-

Ensure the surface of the walls are clean of dust and dirt and fully dry before applying the adhesive. Be sure to use adhesives or cement that are compatible with polystyrene to establish a strong bond.

Apply the adhesive to the back of the cornice, where it will come into contact with the ceiling and wall or just the wall.

Attach the cornice to the marked positions on the ceiling and wall, ensuring a secure fastening.

Remove any excess adhesive with a scraper. As the cornice is lightweight, it is not necessary to support the cornice while the glue dries.

Remember: Always cut the angle first before cutting the piece to the correct length.

-

Measure the length of the wall where you plan to install the next cornice piece from the tip of the previously fitted piece to the corner.

Cut the corner angle before cutting it to length.

Fit the new cornice piece to ensure it aligns perfectly with the first piece before applying adhesive, attach the cornice to the marked position on the wall.

Be sure to align the pieces precisely.

Continue around the room.

-

You can use the adhesive to fill gaps, cracks and over joints to get an even look.

Use a paintbrush damped with water to finish and smooth adhesive off.

Allow the adhesive to dry completely before painting.

Once dry, you can paint the cornice to match your room's décor with any good-quality acrylic paint.

Apply one or two coats of paint using a brush.

Let the paint dry as per the manufacturer's instructions.

-

Finally, stand back and admire your DIY cornice masterpiece!

The cornice adds a touch of sophistication and elevates the overall ambience of the room, especially when when LED lights are added.

Complete The Look With LED Lighting

CORNICE & LIGHTING INSTALLATION

Elevate the ambiance and create a captivating atmosphere with a simple addition that will leave a lasting impression. With the flexibility offered by ShadowLight Cornice, seamlessly integrating LED lights has never been easier!

When marking the positions during your cornice installation, allow an additional 2 to 2.5cm from the ceiling down to create a gap specifically for LED light strips to sit on the cornice surface.

Carefully place the LED lighting within the designated gap, allowing it to follow the contours of the cornice. Connect the lights to a power source, and watch as your space is transformed into a captivating haven with a mesmerizing glow.

Hear It from Our Customers

FREQUENTLY ASKED QUESTIONS

LEARN MORE ABOUT OUR CORNICES

Have any queries or need assistance? Check out our frequently asked questions below. Can't find what you're looking for? Feel free to reach out to our friendly team, and we'll be happy to assist!

-

Polystyrene cornices, particularly those made from high-density moulded EPS, have gained significant popularity because of their user-friendly nature and aesthetic appeal.

The lightweight nature of high-density moulded EPS cornices makes them remarkably easy to handle and install. This quality not only simplifies the installation process but also reduces the labour and time required for completion.

High-density moulded EPS cornices are designed to be durable, allowing them to withstand regular wear and tear. This durability ensures that the cornice maintains its original appearance over an extended period of time.

These cornices possess flexibility that enables them to conceal imperfections present on ceilings and walls. This feature contributes to a smoother and more polished overall look.

-

The most recommended paint for cornices is water-based acrylic paint. Opt for solvent-free paint for interior wall or ceiling cornices.

-

Polystyrene cornices, including the ShadowLight Cornice, are made from fire retardant graded polystyrene. This enhances their fire resistance, reducing the fire hazard.

-

For cornice installation, it's best to use a high-quality, solvent-free construction adhesive. Always adhere to the manufacturer's guidelines. Ensure the surface is clean, dry, and free from loose materials before applying the adhesive.

-

The lightweight ShadowLight Cornices can be effortlessly installed on top of tiles using a solvent-free construction adhesive, allowing easy installation even after the tiles are in place.

-

Polystyrene cornices can be susceptible to accidental damage if they come into contact with a hard object or experience an impact. However, the probability of such incidents is relatively low due to their installation at ceiling height. This positioning keeps them out of reach and less prone to accidental collisions.

-

Absolutely! To repair bumps or dents in cornices, use a gap or crack filler and smooth it with a damp cloth or paintbrush. Once dry, you can repaint the cornice.

-

Yes, since ShadowLight Cornice attaches to the wall, it can be installed beneath an existing cornice. This adds decorative flair to the room and permits the addition of LED lights if desired.

-

While cornices rarely accumulate dust, as gravity tends to cause dust particles to gather more on horizontal surfaces they can easily be cleaned with a simple wipe with a wet rag.

-

If there's a gap between two cornices at a corner due to the corner not being perfectly 90 degrees, and the cornices cut at 2 x 45-degree angles, use a gap filler adhesive and finish it with a damp paintbrush.

-

Yes! We do offer delivery to the following locations:

Queensland: Brisbane, Gold Coast, Sunshine Coast, Mackay, Toowoomba, Rockhampton

New South Wales: Sydney, Coffs Harbour, Port Macquarie, Newcastle, Central Coast, Wollongong, Maitland

Australian Capital Territory: Canberra

Victoria: Melbourne, Geelong

South Australia: Adelaide